Ohio Manufacturer Keeps Workers Comfortable with Evaporative Cooling

Founded in 1903, the Tiffin Art Metal Company began as a manufacturer of stamped ornamental steel ceiling panels - a very popular architectural detail at the time. In 1928, with the advent of motor vehicles, Tiffin Art Metal evolved as one of the country's two leading manufacturers of large billboards responding to the emergence of motor vehicle traffic. They are still leaders in billboard manufacturing, with products shipping all over the world. Now, Tiffin has over 140 employees and 140,000 s/f of manufacturing space west of Cleveland, Ohio.

THE CHALLENGE IN THEIR FACILITY:

The hot and humid summer months in Cleveland create an uncomfortable environment within the factory. Finding a way to provide temperature relief that would be within their financial reach seemed impossible.

THE SOLUTION:

Committed to their employees’ health and comfort, the leaders at Tiffin Metals sought out solutions with the help of their manufacturer’s rep, Western Reserve Energy Corporation, to improve the comfort level as well as the indoor air.

After thoroughly researching options, Tiffin Metal Products decided to use a two-stage evaporative cooling solution tied to a new building exhaust design. WREC worked with Tiffin's input to design and engineer a solution that met Tiffin's exact needs.

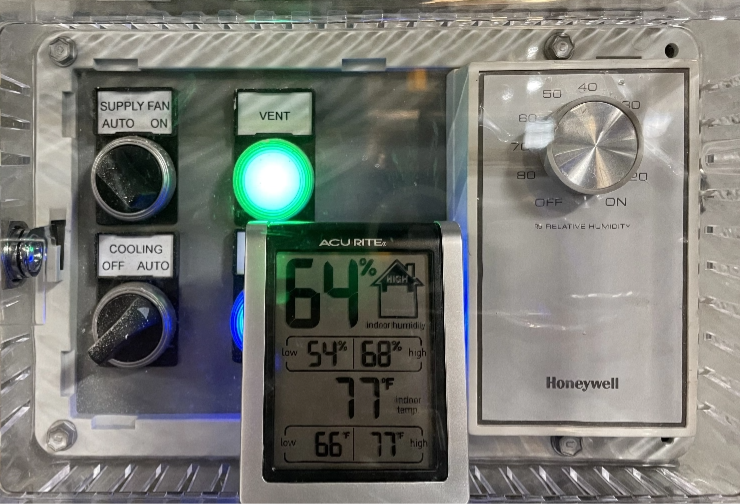

Two Cambridge ESC2-8 two-stage evaporative cooling units with additional humidistat controls were installed and running in early 2022 before the summer cooling season began. From then on, the units worked to deliver the needed temperature relief for the employees.

On average, the inside factory temperature would hold around 77°F when the outside temperature was in the low to mid-90s.

TWO-STAGE EVAPORATIVE COOLING BENEFITS

- Sensible cooling with adiabatic cooling

- Uses plate exchanger with outside air stream and direct evaporative media

- Saturation efficiency up to 120%

- In drier climates can achieve discharge temperature in the mid to high 50's

- EER above 30 in high wet bulb areas

- EER near 100 in drier areas

- No mechanical cooling needed