Cambridge Technical News

No Welding Required

Written by Bill Meyer, Cambridge Applications Engineer

For years we have worked with an industrial retrofit contractor. He often installed vertical S-Series heaters in locations where space was at a premium, both indoors and outdoors. Since Cambridge did not provide a stand for vertical units, he had a structural engineer design a four-legged stand made from 2” x 2” square tubing. The legs would be cut to length in the field and a base plate welded to the leg.

This system worked alright but did cause occasional difficulties.

- Depending upon requirements at the plant where he was installing the heaters, he may have to obtain a burn permit each day, which could result in a delay of an hour or more until the inspector could arrive.

- He also had to ensure a qualified welder was on the crew, with the appropriate equipment.

- When possible, he would set up a welding area within the plant so he only had to set up his equipment once. This simplified the burn permit process, but often resulted in double handling the stands when transporting them to and from the location.

The contractor looked to Cambridge to provide a vertical stand that did not require field welding. Cambridge responded with designing the vertical adjustable stand, which provides vertical adjustment while not requiring any field welding.

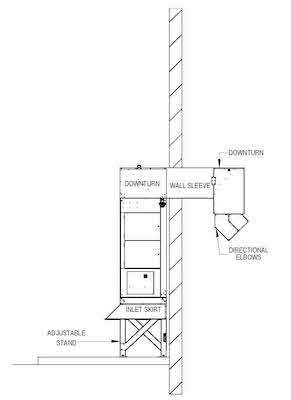

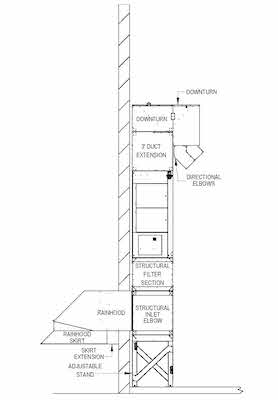

Due to this success, Cambridge has since added the vertical stand, structural inlet elbow, structural filter section, 3’, 4’ & 5’ vertical duct extensions, adjustable elbow, and 24”, 38” & 50” wall sleeves to our standard product offering.

Cambridge has been actively supporting our contractor partners with industrial retrofit heating/ventilating projects for over 40 years. Projects include: aluminum rolling mills, automotive/farming/construction/mining equipment manufacturers, tire plants, electrical appliance & motor manufacturing, corrugators, insulation product manufacturing, steel processing plants, bottling & canning plants, warehousing & distribution centers.